With so many mass-produced Lagers on the market there is no point trying to replicate them – we cannot compete on price – and we wouldn’t want to either when we can do better! What we do is try to make authentic, high-quality Lager with depth of flavour.

It is said in brewing circles that making a high quality lager is a real test of your brewing skills. The clean, crisp flavour of a lager highlights any errors in the brewing process and leaves no place to hide.

We take our lead from traditional German Lager brewing, but we also bypass some of the old methods and add in more modern components too.

This is how we approach brewing Lager:

- All Malt – no adjuncts.

- Multi-step Mash Profile

- Thin Mash

- Weheinstephan Yeast

- Controlled fermentation

We use Pilsner Malt plus a small addition of Vienna Malt for a bit of that “bready” malt flavour. And nothing else. Many mass-produced lagers will have “non-malt” adjuncts (rice, maize/corn) to bring the costs down – but they also thin out the flavour or impart other flavours. We believe our lager has more of the right flavour.

We use a multi-step mash – starting with mash in at 55 to 58 C for a short protein-rest, Raise to 63-64 C for a long beta-rest, raise again to 71-72 C for a short dextrin-rest and finally raise to 76 C to mash-out.

We use a “thin” mash at 3.5 litre/kg of grain – this helps the beta-amylase enzymes work to ensure a dry finish to the beer to allow a crisp taste. This gives us some process headaches as our mash tun is sized for 2.5 litres/kg – a typical British ale ratio. We get around this by running two mashes in parallel when brewing lager – yes, it’s hard work – and it makes for a more stressful and longer brew day – but when quality and authenticity are your aim you take the necessary steps.

We use an authentic German lager yeast – we choose W34/70 Weihenstephan and a temperature controlled fermentation. For a lager you do not want to generate esters – these are fruity compounds that we love in our British Ales, but they have no place in a traditional lager. Fermenting cold is the answer, and the initial growth phase of the fermentation is the most critical.

Where we differ from traditional German Lager processes:

- No Decoction Mash

- Pressure Fermented

- New Cryo Hops

We ferment our lager under pressure. There is research out there that shows the production of esters (fruity flavour compounds) are further reduced by fermenting at 15 psi. This could allow you to ferment the whole batch at “Ale” temperatures – but we still start off cold for a couple of days before gently raising the temperature, we don’t push the limits on temperature. This allows us to get the batch through a bit quicker whilst keeping esters under control, even lower than a traditional cold fermentation according to the research, but the differences may not be perceptible to human senses.

A “noble” hop is used for German lagers. Hallertau Mittelfruh is a classic example that gives a clean hop bitterness. We are using a more modern hop variety (Loral) that shows strong noble hop character. These are also “cryo” hops – this involves a very cold processing of the hops that preserves volatile hop oils to generate pellets that have appx 50% of the vegetal matter removed, leaving a more concentrated pellet of the most useful parts of the hop cone. This allows lower hop addition to the kettle whilst still achieving the same bitterness and flavour extraction that we want – our Lager hop bitterness and flavour are higher than most mass-produced Lagers – for us, flavour is king! And the cryo hops make it a bit easier to clean the kettle out after the boil. (Brewers spend more of their time cleaning than they do brewing! Sanitation is also king!)

As you can see, we are not wholly traditional – pseudo-traditional if you like, or maybe even trad-lite – but, we think we strike the right balance to achieve a high-quality lager that has our own stamp of originality on it.

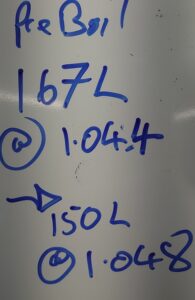

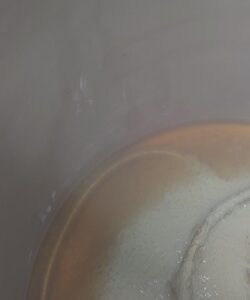

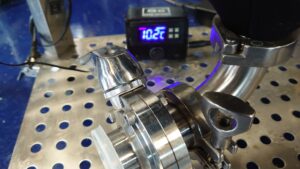

Below are a selection of pictures from the last Lager brewday. (Target volume and SG, Bright wort in kettle, Knock out temperature, Bright wort to fermenter, White foam head in fermenter)